VIBRATORY CONVEYORS FOR FOUNDRY APPLICATIONS

CONVEYORS DESIGNED FOR ANYTHING YOU CAN THROW AT THEM.

Are you going to push a glowing red casting onto a rubber belt? No. How about hot flowing sand onto an apron or metal belt conveyor? Only if you like to sweep. Only one technology meets the demanding environment of a hot and abrasive foundry, and that is vibratory conveyors from General Kinematics.

MORE THAN JUST CONVEYING

Versatile vibratory conveyors from General Kinematics do more than just move materials. The inherent motion of continuously tossing and throwing material forward creates the opportunity to perform one or more processes along the way. Depending upon your application, conveyors can be engineered and constructed with custom trough designs to handle hot, heavy, and/or abrasive materials in the foundry, including sand, sprue, castings, and dross. Conveyors can be constructed using a variety of materials, including mild or abrasion resistant steel, stainless steel, or special alloys. Special patterns, perforations, and trough thickness can also be specified to meet your application needs.

GK VIBRATORY CONVEYOR BENEFITS:

1. SUPER-DUTY DESIGN

The super duty design of GK vibratory conveyors allows them to excel in foundry applications with very little maintenance and downtime. Should something need replacing, parts are easy to replace and available from GK’s Parts team.

2. EFFICIENT DRIVE SYSTEM

Conveyors with GK’s SYNCRO-CUSHION? coil spring drive require less horsepower to start the machine. Less horsepower required means a smaller motor, and a smaller motor means less electrical consumption and more energy savings.

3. MINIMAL ENERGY USE

GK Conveyors are designed using the principle of natural frequency. This design technique uses the harmonics of the machine to store and release energy through the spring system. That means, once the machine is running, it requires almost no energy to operate.

GK CONVEYOR TECHNOLOGY

General Kinematics offers different types of vibratory conveyors depending on your application. Click the links below to learn more about GK’s different conveyor styles:

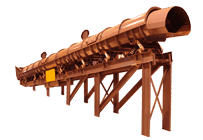

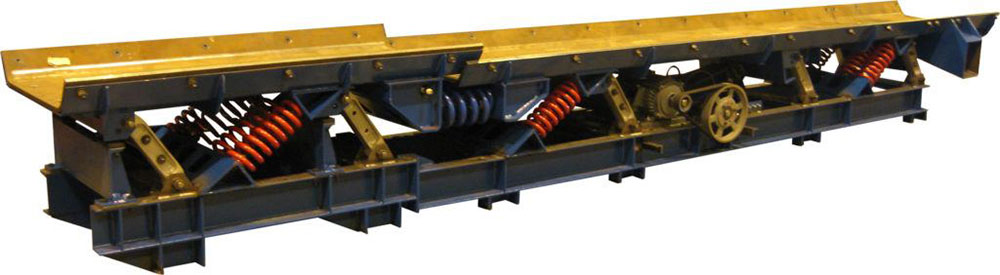

SYNCRO-COIL? VIBRATING CONVEYORS

General Kinematics SYNCRO-COIL? Vibratory Conveyors are designed for the extreme environment of foundry operation. Conveyors feature rugged long life components and heavy-duty construction, and are designed specifically for your material and process.

Trough Design

Recommending the correct trough design is one of the most important factors in meeting your needs for vibratory conveyors. It’s not just fit and finish; our experienced design staff gives careful considerations to product factors such as bulk density, angle of repose, particle size and configuration to name just a few. Further, we offer trough designs with sub-assemblies that speed up trough replacement for high wear applications.

SYNCRO-CUSHION? Coil Spring Drive

Our proven SYNCRO-CUSHION? coil spring drive combines the advantages of natural frequency vibratory action with a rugged drive and trough connection. The result: exceptional performance in high load or adverse operating conditions.

Available in infinite lengths and widths.

Each machine is designed specifically for your application so you know it will work.

SYNCRO-COIL? drive system uses very little energy and can power through adverse operating conditions.

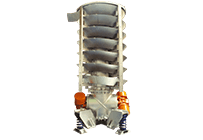

Conveyors can go up, down, or in circles.

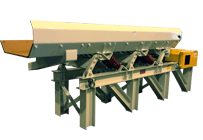

SYNCRO-FLEX? VIBRATING CONVEYORS

SYNCRO-FLEX? Conveyors use rubber shear mounts to support and control dimensional motion, plus function as reactor springs to efficiently store and release energy. Their highly efficient design makes them ideal for low headroom applications such as foods. Simple, uncluttered construction provides maximum cleanliness in chemical and food processing applications along with less maintenance and wear in dusty atmospheres.

FEATURES:Corrosion-free characteristics allow for fast, easy “wash down”.

Rubber shear mounts have been specially designed to provide low stress, trouble-free operation.

Available in custom lengths and widths depending on your application.

SYNCRO-FLEX? “S” VIBRATING CONVEYORS

SYNCRO-FLEX? “S” Vibrating Conveyors with slat spring assemblies offer exceptional performance and value. They are specifically designed for light material loads with long, dependable operating life. Long lasting fiberglass or metal slats require fewer replacement parts as the machine stabilizer and spring are integrated into one simple slat assembly. Each SYNCRO-FLEX? “S” Vibrator Conveyor is engineered to your specific application.

特點:

Low stress reinforced glass fiber slat springs.

Long stroke, low speed operations for reduced conveyor wear

Available in custom lengths and widths depending on your application.

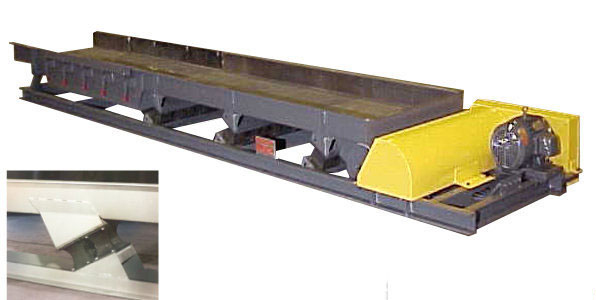

SYNCRO-SHEAR? VIBRATORY CONVEYORS

General Kinematics Under Mill Oscillators are specifically designed to handle the severe conditions found underneath auto-shredders and other abusive applications. Heavy-duty wear resistant troughs handle the impact of falling material while the exclusive General Kinematics SYNCRO-SHEAR? drive is designed to handle the force of even the largest explosions without damage to the conveyor.

General Kinematics super heavy-duty Under Mill Oscillators are designed to take the abuse of explosions and heavy impacts found under auto and other types of shredders. Decks are made of wear plate for long life, and drives are located in the rear of the unit for easy maintenance.

Energy saving low horsepower drive reduces operating costs.

Rigid bumper system to prevent over-stroke of trough due to overloading, explosions, or heavy impacts.

SYNCRO-SHEAR? spring system eliminates issues found with coil springs in this application.

Long lasting wearplate troughs.

Rear mounted drive for easy maintenance access.