SAND COOLING EQUIPMENT

he right temperature sand makes a big difference for downstream processing. Improper temperature or moisture content can throw off your entire casting operation. GK provides a wide range of sand cooling and water addition technology to accurately condition your sand. GK has the right technology to improve your foundry process.

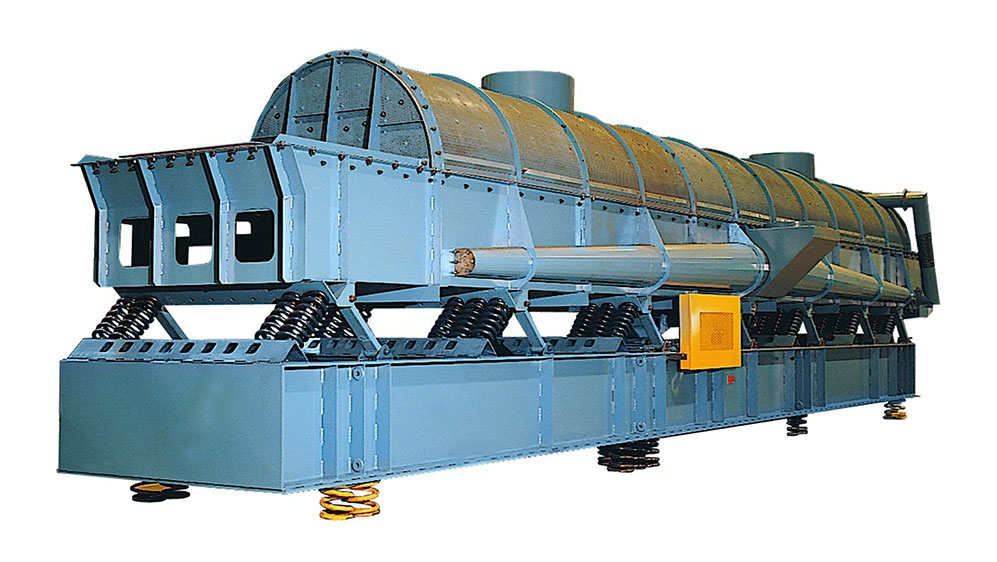

VIBRATORY FLUID BED SAND COOLERS

General Kinematics Vibratory Fluid Bed Sand Coolers are specially designed for evaporative cooling or drying of foundry sand. Air distribution decks are engineered to provide complete control of airflow for exceptional drying or cooling efficiency.

FEATURES:Choice of vibratory balancing styles or isolated designs to suit specific installation requirements for foundations or structures.

Custom designed to meet your sand cooling throughput needs to 500 tons or greater.

Infinitely adjustable controls provide variable retention time and improved process efficiency.

Inlet air distribution manifolds minimize costly stationary ductwork and supports.

High efficiency, low horsepower Two-Mass drive reduces energy requirements.

VIBRA-FIN? BULK MATERIAL COOLER / CONDITIONER

Uniquely flexible for a wide range of continuous processing needs, GK’s VIBRA-FIN? indirect sand cooling units are ideally used for heating, cooling, or drying foundry sand or other free flowing bulk materials. VIBRA-FIN? sand coolers are available in a variety of configurations, and utilize vibratory agitation while passing a cooling medium through the material bed to indirectly absorb and dissipate heat.

FEATURES:Cool continuous hot material flow streams indirectly with counter flow cooling medium beneath the material conveying surface.

Cool dusty, oxygen sensitive or hygroscopic materials in a sealed and controlled environment.

Stainless steel, abrasion resistant and other construction options for contact materials.

Dynamic balancing and Isolation available for above grade installations.

Variable flow rate option to modulate residence time where required.

Sealed feed and discharge connections eliminate the need for dust collection.

Once through or recirculation of the cooling medium.

Cooling Towers and Refrigeration available for recirculated cooling medium.

Totally enclosed heat exchanger for continuous processing.

Easy to maintain, self cleaning design.

Optional hydraulic, electric, or pneumatic shut-off or flow control gates.