SCREENING & CLASSIFICATION

General Kinematics vibratory screens and classifiers separate material by size or density. Multiple cuts can occur in each machine when required. GK Two-Mass designs help eliminate blinding with higher energy imparted to the material and with superior performance. In addition, the Two-Mass design means the unit will never dampen out in overload conditions compared to direct drive designs.

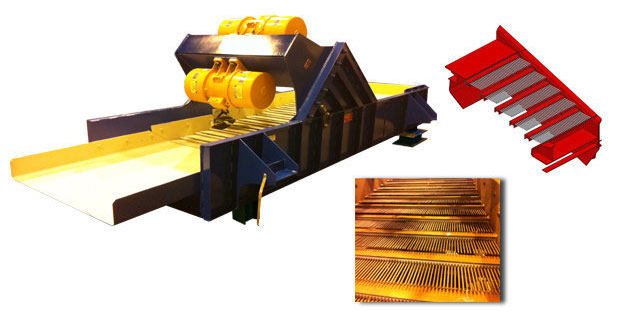

FINGER-SCREEN? SPECIALTY ROD DECKS

General Kinematics FINGER-SCREEN? Rod Decks are designed for separation of difficult material that is prone to sticking or blinding in traditional screening applications. The secret behind the rod decks ability to perform lies in the flexibility of the individual rods within the deck section, while maintaining the designed screening tolerance.

The heavy-duty design of GK Rod Decks allows for abrasive, heavy, wet, or otherwise difficult material to easily cascade through the sorting area.

The high-stroke capabilities of the GK’s FINGER-SCREEN?, combined with the flexibility of the engineered rod deck assemblies, creates a versatile and high performance screening solution to maximize sorting in your process application.

Separates material that can blind tradtional screening surfaces.

Allows for flexibility while maintaining screening tolerances.

GK rod decks allows for abrasive, heavy, wet, or otherwise difficult material to easily cascade through the sorting area.

FINGER-SCREEN? VIBRATORY SCREENERS

The FINGER-SCREEN? vibratory screener is a patented, non-binding design concept for resource recycling. This screening separation machine has proven to be highly successful in a wide range of applications that are prone to hang-ups common to conventional wire mesh screening surfaces.

HOW IT WORKS

The superior performance of vibratory processing and the simple jam-proof movement over our unique FINGER-SCREEN? delivers highly efficient separation and classification. The units vibrating motion spreads material evenly across the deck for maximum separating efficiency. Our team offers the vibratory screeners in multiple sizes of separating decks to enhance classification while staggered finger positions help to prevent material bypass. Separation performance is enhanced as material freely cascades through the unit — with less “trapping”. The result: fast, smooth continuous material flow throughout the entire separation and classification process.

Vibratory motion evenly spreads material for maximum classification efficiency.

Staggered fingers on the vibratory screener prevent material bypass.

Cascading material flow helps separate entrapped items.

Unique “cam-out” surface helps eliminate catching and binding.

Tapered fingers gradually classify and free tangled materials.

Open below deck design permits “free fall” of material to lower collecting deck.

Custom-engineered to meet your specific classification requirements.

Modular deck construction permits easy deck replacement.

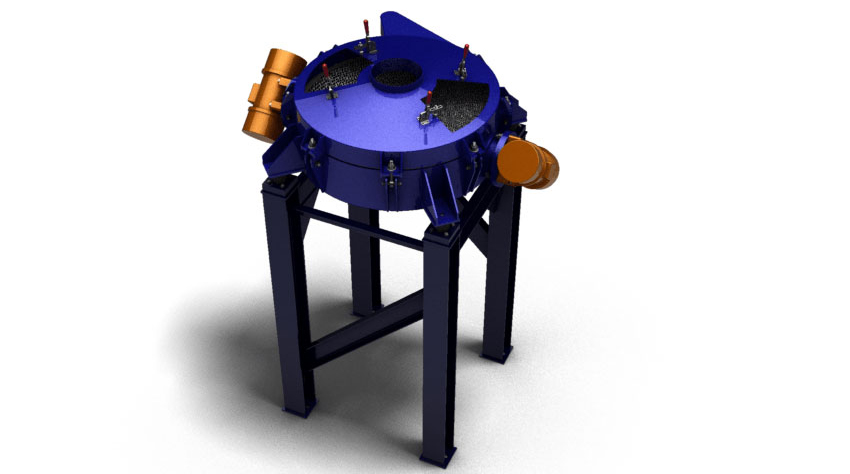

OMNI-SCREENER?

General Kinematics vibratory OMNI-SCREENER? produces superior control and classifying results in bulk material processing applications. Units can have multiple deck surfaces for variable screening. Square shape makes screen changes a snap using simple tensioning procedures.

FEATURES:Spiral flow of product from central in-feed point develops extended resonance time for near-size particles.

Simple, self-contained, motorized drive with variable vibration amplitude and adjustable angle of attack permits rapid adjustments to achieve optimum screening efficiency.

Low headroom construction can be totally enclosed where required.

Available in carbon steel, stainless steel, and food grade construction.

OMNI-SCREENER? C-SERIES VIBRATORY SCREENS

General Kinematics OMNI-SCREENER? C-Series Vibratory Screens utilize our proven screening technology with a round body design to utilize commercially available replacement screens. OMNI-SCREENER? C-Series screens allow for high capacity wet or dry screening in a compact, low headroom design.

The two motor design of the OMNI-SCREENER? C-Series allows for increased throughput and material flow with difficult materials. Heavy-Duty custom designs are available in mild steel, stainless steel, or other exotic materials to meet your process or material characteristics.

Spiral flow of product from central infeed point develops extended residence time for near-size particles.

Simple, self-contained, motorized drive with variable vibration amplitude and adjustable angle of attack permits rapid adjustments to achieve optimum screening efficiency.

Low headroom construction can be totally enclosed where required.

Available in carbon steel, stainless steel, and food grade construction.

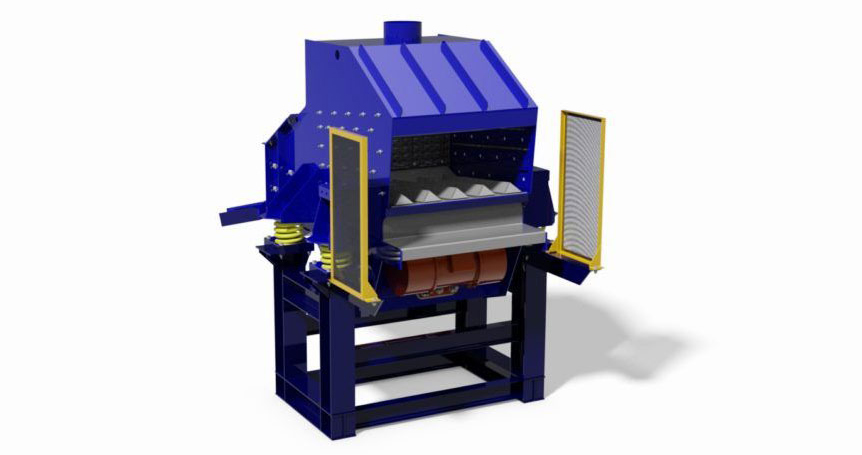

STM-SCREEN? EXTRA LARGE VIBRATING SCREENS

The STM-SCREEN? Two-Mass, extra large vibrating screens for bulk processing utilize GK’s proven Two-Mass, natural frequency drive design. This load-responsive design is capable of longer material retention times to work the material more. Dual in-board vibratory motors eliminate expensive belts, shafts, and bearings for increased uptime, longer service intervals, and the lowest cost of ownership available in a vibratory screen package.

The STM-SCREEN? screens are field proven and have four to twelve locations for drive bracket attachment to the screen body to evenly spread the drive force / energy.

Available in STM-S? Single Deck, STM-D? Dual Deck as well as cascading deck standard models, the STM-SCREEN? is modifiable to address your specific requirements.

Load responsive.

Capable of longer material retention times to work the material longer.

High up-time, minimal down-time design with unmatched structural integrity.

Available in standard sizes to handle from 580 – 1800 metric tons per hour.

Custom sizes, decks, and other options are available – Contact the GK team (using “Contact” tab) to request more information.

SINGLE KNIFE DE-STONER? AIR CLASSIFIER

The GK Single Knife DE-STONER? is a fully proven design operating efficiently in many tough separating applications. It is the only dry classifying system capable of handling continuous, high volume production.

The completely dry system eliminates water handling and other “wet” system problems, yet can easily handle moist materials.

Vibratory action and high velocity / low pressure air streams fluidize and stratify material according to difference in terminal velocity of particles to remove heavy items such as glass, metallics, stones, dirt, etc.

How it works

Vibratory action moves material, with high density material settling to the bottom of the trough.Fines drop out section (optional) removes smaller particle sizes like broken glass or dirt before reaching air fluidizer.

Air fluidizing section assists in stratifying material.

High velocity, low pressure air stream is directed through material flow.

Material conveys into air stream. Heavier materials fall through air stream to discharge chute.

Marginal density material is caught on adjustable slope plate and falls back into discharge chute.

Acceptable lighter materials are carried beyond plate and travel to product discharge.

Ultra light or thin film materials like paper and plastic film are removed through air exhaust on stationary hood over discharge.

SUCCESSFUL SEPARATING AND CLASSIFYING APPLICATIONS INCLUDE:

Commingled materials C&D materials Shredded MSW Shredded auto scrap fluff Bio-mass fuel RDF fuelFEATURES:

The DE-STONER? uses air instead of water to separate heavy product from light product, eliminating the mess and environmental hazards water separation creates.

Adjustable to obtain varying degrees of separation. Adaptable to a wide variety of products.

Separates material of different density, or of same density with different particle size.

Virtually jam-proof. No moving separator parts.

Low energy demand with single low HP motor and GK’s proven Two-Mass design.

Heavy-duty, built to last construction.

Inherently simple, fully isolated design minimizes foundation requirements.

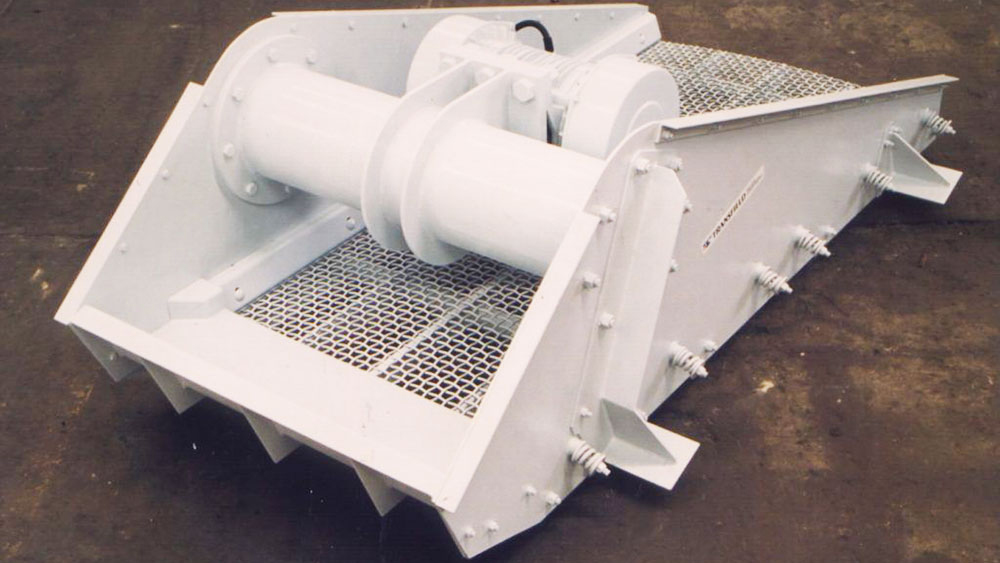

TWO-MASS VIBRATORY SHAKEOUTS

General Kinematics Two-Mass Shakeouts boost throughput. Our simple Two-Mass, High Frequency, Shakeouts automatically compensate for varying load conditions, assuring full, non-dampening performance.

Driven with sealed vibratory motors, GK’s Two-Mass Shakeouts eliminate the need for V-belts, pivoted motor bases, couplings, and large and expensive bearings. Drive is mounted on a separate exciter mass, completely isolated from the high intensity impact action of the shakeout deck.

Unique Two-Mass design automatically compensates for varying load conditions, assuring non-dampening shakeout performance.

Driven with sealed vibratory motors, GK’s Two-Mass Shakeouts eliminate the need for V-belts, pivoted motor bases, couplings, and large and expensive bearings.

Drive is mounted on a separate exciter mass, completely isolated from the high intensity impact action of the shakeout deck.

Units feature low horsepower, adjustable amplitude control, and exceptionally quiet operation.

DIRECT DRIVE VIBRATING SCREENS

General Kinematics Direct Drive Vibrating Screens are unmatched in reliability and performance. With Two-Mass or brute force designs and extra-heavy duty bodies, screens withstand any material you can throw at them.

MODEL DS AND VS SCREENS

The Model DS and VS Vibrating Screens provide a simple, cost effective solution for your screening process. Our standard units have few moving parts, which adds up to cost effective operation and lower maintenance costs. The wide range of available screen sizes can be set at various angles and fitted with a variety of screen dressings to meet your process requirements.

Contact General Kinematics for more information on sizing and options.

Available in brute force or Two-Mass drive systems depending on your application.

Various screen designs including rubber deck, perforated, or finger screen systems.

Standard sizes and custom designs available to best fit your process.

PETROLEUM COKE DEWATERING

General Kinematics Petroleum Coke Dewatering System produces continuous, reliable dewatered flow stream for fast and efficient processing of pet coke. Dewatering units utilize GK’s patented dewatering deck technology which eliminates blinding and constant screen maintenance. Feeders utilize proven two-mass technology for energy efficient operation. Available as fixed or mobile units depending on your process and application.

FEATURES:Eliminates multiple handling

Minimizes labor requirements

Enhances production safety

HIGH FREQUENCY SCREEN OR FEEDER

The GK High-Frequency Screen or Feeder equipped with the innovative, patent-pending Structural Springs, is a fiscally responsible solution for powder and bulk processing. Structural Springs also function as legs to create a simplified design. The smaller natural frequency motor provides a more cost agreeable solution compared to brute force.

The combination of structural springs and natural frequency design allows for longer units in comparison to brute force design.

In addition, the High-Frequency Screen or Feeder (patent pending) is backed by GK technical support.

High-Frequency provides better fines screening

Fluidizes material

Structural Spring provides higher spring rate in small space

Low stroke provides extremely low dynamic force allowing equipment to be placed directly on the floor

Smooth startup and shutdown

Needs very little clearance

Smaller Footprint

Safe, simple operating design

Cost Effective

VIBRA-MILL? VIBRATORY LUMP BREAKERS

Shakes, agitates, vibrates, tumbles, and abrades up to 4 foot lumps to minus 20 mesh grain size. Automatically.

The VIBRA-MILL? Vibratory Lump Breakers reduce agglomerations, clumps, and lumps in bulk materials. High energy vibration, combined with tumbling action, reduces lumps back to grain size. Once lumps are reduced, additional screening is achieved, allowing for grading of materials by size. Overs can then be collected and reintroduced to eliminate waste.

Special vibratory service motors for increased uptime.

Various feed options depending on application.

High capacity reclamation rates.

Simple, open tub design for easy loading.

Single jam-proof deck.

Provides fines removal.