ROTARY & VIBRATORY PROCESSORS

Processing of bulk solids accurately and efficiently is important to the integrity of the product and the performance of the processing system. General Kinematics vibratory mills, rotary drums, rotary dryers, and other products below can enhance your processing systems. Our rotary and vibratory processing solutions are designed for fine grinding, coating, mixing, agglomerating, heating, cooling, and more. Click each product or category below to learn more…

HMG? VIBRATORY TUBE CRUSHER

General Kinematics patent pending HMG? Vibratory Tube Crusher quickly breaks down material. Rapid pulsation of media within the tube fractures material into smaller particles ideal for final comminution in GK’s VIBRA-MILL? Grinding Drum.

FEATURES:Can be totally sealed for a dust free environment.

Low horsepower drive reduces energy consumption and electrical costs.

Available in custom sizes to best fit your throughput and application.

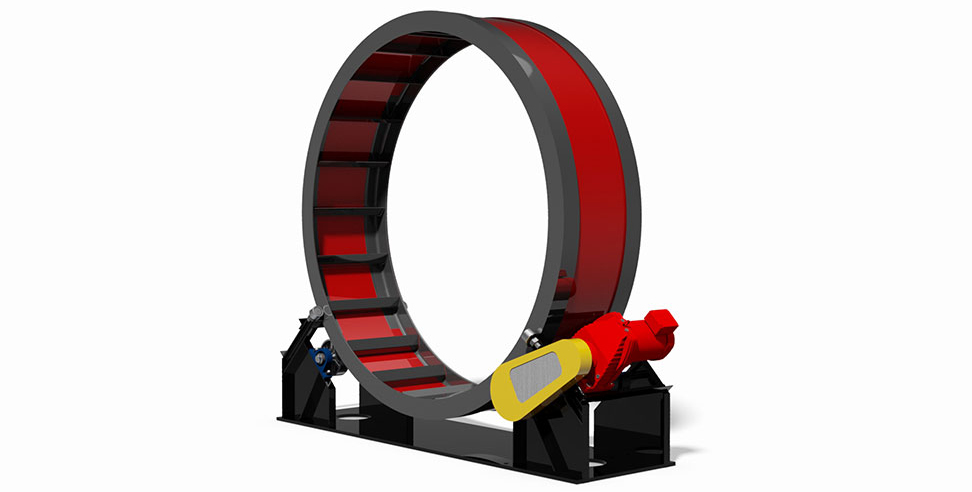

ROTO-VEYOR?

General Kinematics ROTO-VEYOR? is a low-maintenance vertical conveying solution for elevating and metering bulk materials.

The simple design of the ROTO-VEYOR body has no moving parts in contact with the material being processed, reducing downtime and maintenance. Lifting paddles inside the water wheel receive material, elevate it, and then deposit it into a chute or onto a conveyor.

GK’s ROTO-VEYOR is available in mild or stainless steel, and can be custom engineered to fit into new or existing processes.

No moving parts contact process material, significantly reducing cleaning and maintenance.

Elevate and evenly meter or mix materials.

Available in standard or custom configurations to best fit your process requirements.

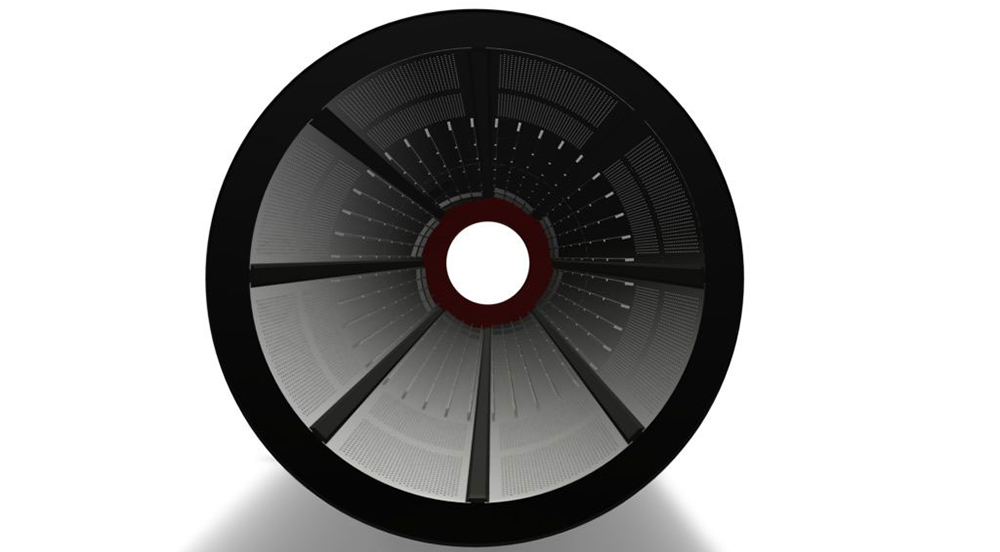

VIBRA-DRUM? GRINDING MILLS

VIBRA-DRUM? Grinding Mills are proven in dozens of milling applications. Grinding processors are achieving impressive energy savings (35-50%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary mills.

Exceptional grinding performance and energy savings are the result of the VIBRA-DRUM? unit‘s natural frequency design. A sub-resonant, two mass drive and spring system alternately stores and releases grinding power. Once in motion, energy is only needed to move the grinding media as a fluid mass, and to overcome frictional losses.

VIBRA-DRUM? has been proven to grind plastic, composites, food, coatings, pharmaceuticals, rubber, additives, polymers, minerals, cosmetics, ceramics, and more. Contact GK to find out if we can improve your grinding process.

The VIBRA-DRUM? excels at mechanochemical grinding, cryogenic grinding, agglomeration, dry product cleaning, polishing, recycling, hydrometallurgy, casting cleaning, and micron grinding.

Low energy requirements for efficient operation.

Can use any type of grinding media.

Available in standard and custom sizes.

ROTARY COOLING DRUMS

General Kinematics Rotary Cooling Drums efficiently reduce product temperatures while tumbling material. Rotary Cooling Drums can be designed using direct cooling, using ambient or chilled air, or indirect cooling, using cooled air or liquid to cool material through the cylinder wall. Each drum is custom engineered to meet your process specifications, and can be supplied as a single unit or integrated processing package.

FEATURES:Drum can be driven via chain or through friction drive, depending on application.

Available in mild or stainless steel.

Internal flighting and lifting sections customized for your application.

Direct or indirect cooling options.

Available with auxiliary vibratory infeed and take away conveyors.

ROTARY PROCESS DRUMS

Rotary Process Drums from General Kinematics can be designed for drying, mixing, granulating, coating, heating and more. Available in mild steel or stainless steel, rotary drums can be outfitted with a variety of options for processing your product.

FEATURES:Drum can be driven via chain or through friction drive, depending on application

Available in mild or stainless steel

Internal flighting and lifting sections.

Available with auxiliary vibratory infeed and take away conveyors.

ROTARY DRYER EQUIPMENT

General Kinematics Rotary Dryer is custom engineered to maximize the unique drying and processing needs of your material. GK Rotary Dryers use rotary motion to lift and cascade your material through the hot gas stream, evaporating moisture evenly. Dryers can be designed using various drying technologies, including direct drying in counter-current or co-current flow, or indirect drying, utilizing external heat applied to the exterior of the drum shell.

GK rotary dryer designs use extra heavy-duty components for extended up time and reduced maintenance. Material contact surfaces are manufactured from wear resistant materials, so drums will last a long time between servicing. Rotary trunnions and rings are forged for superior strength and durability, and are easy to replace or resurface.

The engineers at GK will work with you to design a complete drying system that works. Couple your rotary dryer with GK’s proven vibratory material handling equipment to pre-process, feed, and deliver your dried product to the next step in your manufacturing process.

Aggregate

Agricultural products

Biomass materials

Fertilizer

Gypsum

Limestone

Municipal waste

Sand

Wood and organic fibers

ROTARY DRYER FEATURES:

Rotary Dryers internal flighting and lifting sections customized for your application.

Direct drying available in counter-current or co-current flow designs.

Dryers can be designed to use various readily available fuel sources.

Available with auxiliary vibratory in-feed and take away conveyors.