VIBRATING FEEDERS

General Kinematics vibratory feeding technology is ideal for feeding and metering a wide variety of bulk materials. From pile activation to precise product metering, GK has the right vibratory feeder technology for your process. GK’s Two-Mass variable frequency design allows for up to 100% process turn-down without changing motor speed and continues operation even during surges and overload conditions.

AIR-DUO? PNEUMATIC FEEDER DRIVES

AIR-DUO? Pneumatic Feeder Drives from General Kinematics puts more energy into your feeding systems than standard pneumatically driven feeder designs. Utilizing a two-mass spring system, energy is amplified to do more work with less energy. Finite control of product flow rate is easily accomplished with the simple turn of a valve. AIR-DUO is available as an option on GK’s S-SERIES feeders and other vibratory equipment.

Contact a GK Product Specialist for more information

AIR-DUO? drive requires minimal energy to produce maximum results.

Low maintenance design for increased uptime.

Optional controls available to integrate into existing systems.

Provides wide range of feed rates in a single unit for optimizing process throughput.

HULA-HOPPER? BIN ACTIVATOR / FEEDER

The General Kinematics HULA-HOPPER? Bin Activator is an improved vibratory equipment concept based on operating principles proven in thousands of General Kinematics installations. Within a single, extremely low headroom unit, HULA-HOPPER? combines material activation, infinitely variable flow rate control, and positive flow shut-off all into one bin activator unit, yet installation, service, and operating costs are dramatically lower than for comparable bin activator systems.

HULA-HOPPER? Bin Activator eliminates many problems associated with more complex, brute force vibratory machinery because of its simplified operating design. As a Two-Mass vibratory unit, HULA-HOPPER? uses a low horsepower motor drive, therefore electric power needs are minimal. Orbital action eliminates compacting and bridging because only material drawn out is activated.

Infinitely adjustable flow control using GK’s VF wheels or electronic VFD.

Extremely low headroom design reduces bin activator height requirements.

Easy to service design.

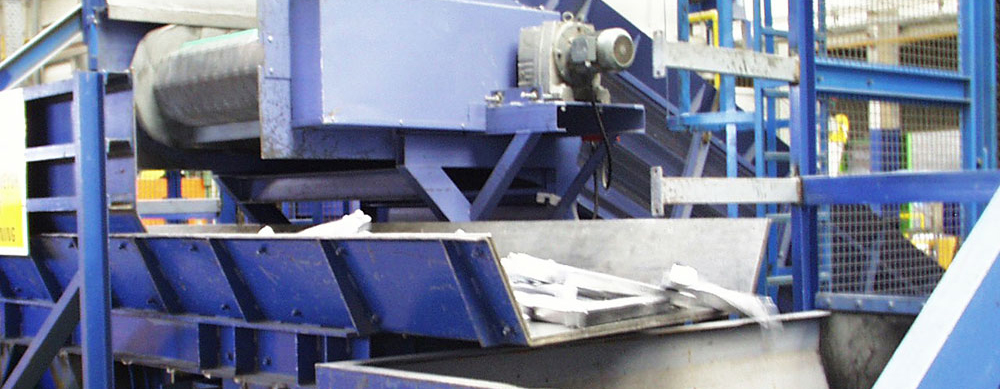

PARA-MOUNT II? VIBRATING FEEDERS

Proven performance and maintenance free operation make PARA-MOUNT II? Vibrating Feeders the first choice in vibrating feeders for the most demanding applications. PARA-MOUNT II? Vibrating Feeders in either fixed or Variable Force configurations utilize a sub-resonant two-mass system. Mass A (the exciter) energizes mass B (the deck assembly) through precision engineered coil springs. Only small amounts of energy are needed to maintain the natural energy stored and released by the spring system. What this means for you is increased feed capacity, lower energy costs, and exceptional reliability and ease of maintainability. PARA-MOUNT II? vibratory feeders do more work with less energy, thanks to our two-mass, natural frequency design. Whether you are charging a feeder or metering sand or castings, each feeder is designed specifically to work to enhance your process.

FEATURES:Two-Mass vibratory drive can be designed with low horsepower foot mounted or double c flange motors.

Simple, extra-heavy duty construction for years of trouble free service.

Two-Mass, sub-resonant natural frequency design is self-compensating to automatically maintain constant feed rate for varying load and material changes.

Significant annual energy savings over brute or direct force designs.

Engineered to be low maintenance for continuous uptime.

Extra-Heavy duty design withstands heavy parts and abrasive materials.

S-SERIES STANDARD SERIES VIBRATORY FEEDERS

The General Kinematics S-SERIES Standard Series Vibratory Feeders are ideal for handling a wide range of light duty, free-flowing products, including foods, ingredients and chemicals. Feeders can be designed using two-mass or brute force drive electro-mechanical drive systems or pneumatic drives. Other models in stainless steel and hooded are available to meet your special process flow requirements. Contact us today for comprehensive design and application assistance.

For dimensions and sizes, click here.

Wide range of sizes for various applications.

Pre-engineered models are cost effective.

Simple design with energy-saving low hp motorized drive.

Easy-to-maintain FRP leaf springs.

Isolated base with leaf springs produces low dynamic reaction.

Units can be base mounted or suspended overhead.

TWO-WAY? HORIZONTAL FEEDERS

TWO-WAY? Feeders from General Kinematics open up a wide range of process possibilities. The TWO-WAY? unit’s bi-directional conveyance allows you to alternate material flow for multi-directional product processing, for rejection of bad product, or any other process which may require multi-directional conveyance from a single unit. The unit’s completely horizontal stroke shuffles material with no impact and a significant reduction in noise. Available in straight and all new bidirectional curved designs.

FEATURES:Available in straight and curved configurations.

Stainless or carbon steel construction depending on your application.

VIBRA-FIN? BULK MATERIAL COOLER

General Kinematics VIBRA-FIN? Bulk Material Cooler is ideal for cooling or heating granular materials. Processing material to accurate and specific temperatures with indirect cooling and heating through heat exchange provides for evenly conditioned material. No dust collection or airflow required. Processes materials and plastics 1/8″ or smaller.

FEATURES:No air needed cutting down on auxiliary equipment.

Metered material output.

Indirect heating and cooling.

High and low-temperature probes.

Custom cooling bundles.

STANDARD BIN ACTIVATORS

General Kinematics Standard Bin Activators are designed to feed and meter bulk materials. GK’s non-compacting “first in – first out” design discharges material without particle deterioration, and eliminates many of the bridging and ratholing issues found in other forms of bin activation.

FEATURES:Available in most standard as well as any custom size necessary for your application.

Driven with a compact vibrator, units have very few moving parts for low maintenance.

Units are available in mild, stainless, or any material you require for your process.

INDIRECT COOLER FOR HYGROSCOPIC MATERIALS

General Kinematics’ New Alternating Flow Cascade (AFC) Indirect Cooler significantly improves the cooling process for Lithium Chloride and other hygroscopic products. Based on the company’s core Two Mass Technology, the cooler is designed with linear conveying coupled with the true horizontal drive action evenly spreads and maximizes the product contact with the cooling decks. The modular deck design further tumbles the product for increased uniform cooling. Designed with a liquid plenum beneath each deck, cooling fluid is circulated in an opposed direction to the product, following a serpentine motion to optimize the cooling effect. Sealed feed, discharge, and deck chambers eliminate the need for dust collection and prevent moisture from entering making this unit ideal for hygroscopic products.

FEATURES:Stackable design to further extend the cooling length

Tumbles material after each turn for uniform cooling

True horizontal drive action maximizes product contact duration with cooling deck

Modular Deck Design allows customizable cooling zones

Available with various steel trough construction including stainless steel, abrasion resistance and High nickel alloy for highly corrosive products

Conveyor rate is controllable

Eliminates need for dust collection

Sealed chamber for hygroscopic materials

Easy access doors for material handling

GK’s Two-Mass design requires a fraction of the horsepower of a conventional machine

Vibration monitor system included