VIBRATING CONVEYORS

General Kinematics continues to perfect vibratory conveyor technology, and expand its use in thousands of bulk handling and processing applications. Today we’re efficiently moving and processing a wide range of materials – from heavy castings to paper scrap. This includes castings, sand, foods, pharmaceuticals, scrap metals, ores, minerals, coal, ash, trash, forest products, and more, all with versatile vibrating conveyors that move materials at the volume and speed you need.

KWIXTROK? HORIZONTAL MOTION CONVEYORS

The operating principle behind KWIXTROK? is simple and efficient – a smooth forward horizontal motion followed by a quick return. Material moves ahead through differential friction along the pan without the bouncing and vertical impact experienced with a conventional vibrating conveyor. Gentle material flow and simple, uncluttered construction make this linear conveying system ideal for moving bulk materials such as foundry sand, chemicals, scrap, and food products.

FEATURES:Drive can be located anywhere along the trough for more installation flexibility.

Simple drive eliminates noisy gears and costly maintenance.

Occasional lubrication is done through centrally located lubrication system.

Can be configured as straight, oval, circle, rectangle “s” curve, or any combination of paths.

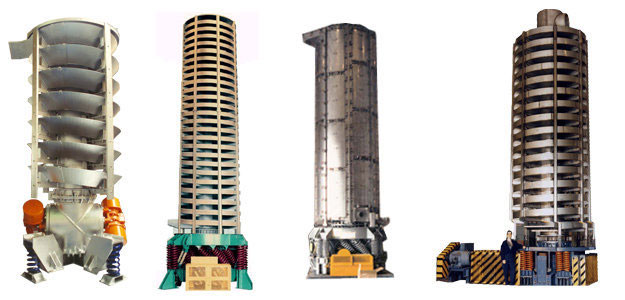

SPIRA-FLOW? VIBRATING SPIRAL ELEVATOR

General Kinematics SPIRA-FLOW? vibrating spiral elevators and conveyors for processing offer unmatched performance with added process features. Available in infinite lengths and heights, GK Spiral Conveyors are custom built for your specific application.

Technically advanced vibrating spiral conveyors are more than just an elevator for your product. SPIRA-FLOW? Vibrating Spiral Conveyors can be equipped for direct or indirect drying, direct or indirect cooling, coating, and can be designed to convey material up or down. Vibrating spiral elevator units are available in stainless or mild steel, open or enclosed. There is no limit to what a GK SPIRA-FLOW? can do.

Direct drive or Two-Mass designs available.

Can be open or enclosed, depending on your application.

Elevate or lower products on the vibrating spiral conveyors.

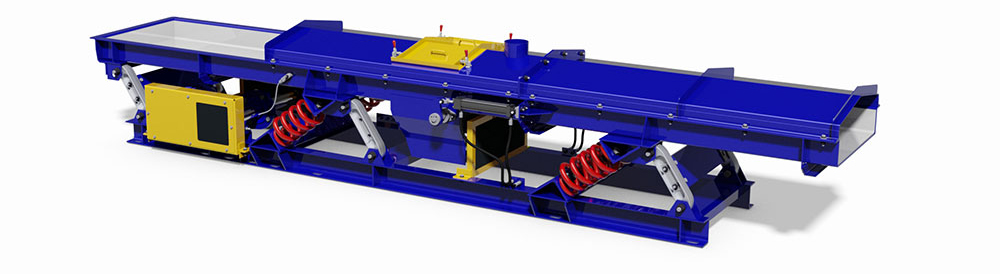

SYNCRO-COIL? VIBRATORY CONVEYORS

General Kinematics SYNCRO-COIL? conveyors are designed for heavy or medium-duty material load applications. They feature rugged, long life alloy coil springs and are ideal for applications with heavy-duty trough construction, large material loads, or operation in dusty or difficult atmospheres.

SYNCRO-CUSHION? Coil Spring Drive

Our proven SYNCRO-CUSHION? coil spring drive combines the advantages of natural frequency vibratory action with a rugged drive and trough connection. The result: exceptional performance in high load or adverse operating conditions.

A Balancing Style for Every Application

In many installations, the transmission of forces to the surrounding supports or building steel must be reduced to a minimum. General Kinematics offers many types of counterpoised designs to adsorb or isolate reaction forces. Learn more about GK’s balancing styles here.

Versatile Design Options – Light and heavy-duty construction as well as different isolation and drive configurations depending on your application.

SYNCRO-CUSHION? Coil Spring Drive – Coil spring connection to trough offers protection to drive components should an overload occur.

Aluminum Rocker Legs – Aluminum legs offer the strength of steel while significantly reducing vibrating weight of machine. Aluminum also quickly conducts heat away from the bushings. Less weight and less heat mean less wear on components and more uptime for your equipment.

Balanced and Isolated designs – In many installations, transmission of forces to the surrounding supports or building steel is unacceptable. GK offers many different types of counterpoised designs to absorb or isolate reaction forces. These include duplicate trough reactor assemblies, sub-base to earth spring systems, and positively driven balancer mass that moves 180 degrees out-of phase – to name just a few. GK will work with you to determine which design will work best with your process application.

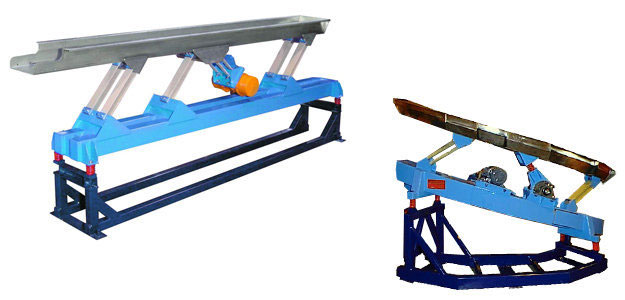

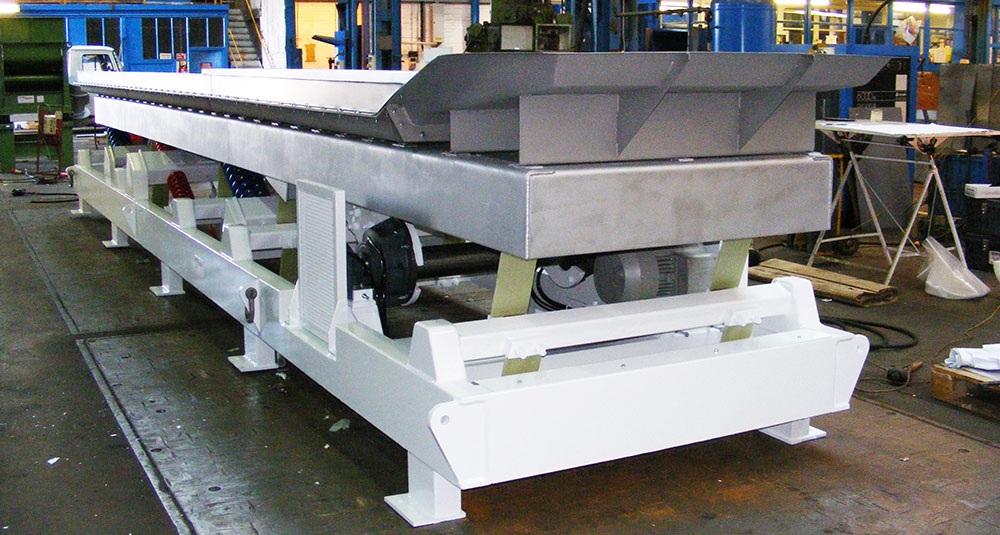

VIBRATING TRANSFER CONVEYORS

Light duty Vibrating Transfer Conveyors are ideal for moving a wide range of free-flowing materials in food and chemical processing. Natural frequency conveyor design uses less energy while efficiently moving your material. Backed by more than 40 years of vibratory process equipment experience, General Kinematics is uniquely qualified to meet your application needs.

FEATURES:Economical, low HP motorized drive — CL I and CL II available.

Easy-to-clean FRP leaf springs.

304 or 316 stainless steel troughs with covers available.

Isolated base with coil springs for low dynamic reaction.

Standard designs are easily customized to meet your application requirements.

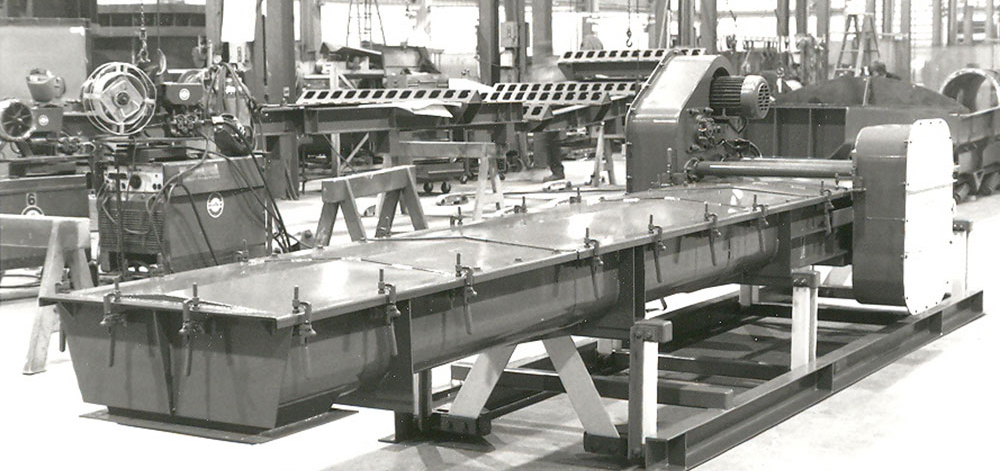

TOASTER CONVEYORS

General Kinematics conveyors for under toasters, dryers, and coolers are constructed from heavy duty stainless steel to counter-act the effects of heat. All pans have a tightly toleranced flatness to maintain even toasting. Conveyors are accurately balanced to minimize the need for costly foundations and to elevate any sideways movement in the pan, allowing close coupling between conveyor and processing unit.

General Kinematics composite heat resistant slats are used as the spring system. These slat assemblies have been specially developed to withstand the temperatures typically seen under toasters. Steel slats and coil springs are also available.

With many conveyors in the field, General Kinematics understands your requirements for reliable equipment that needs little maintenance. The SYNCRO-COIL? durable drive system gives customers confidence to run on a 24/7 basis.

The General Kinematics toaster conveyors can be designed to include any of the following:

Removable infeed and discharge sections.

Infeed plenum chamber and fan.

Variable speed drives.

Shaft speed monitoring.

Stroke monitoring.

Heat insulating decks.

Complete stainless steel fabrications.

VIBRA-BELT? VIBRATORY BELT CONVEYOR

VIBRA-BELT? Vibratory Belt Conveyors combine the best features of vibrating conveyors and belt conveyors into one superior material handling concept.

The VIBRA-BELT? Vibratory Belt Conveyor has a flexible trough suspended between the sides of a trough provided with General Kinematics proven vibrating conveyor drive and reactor system components. The result is an improved belt conveyor system, adaptable to a variety of materials and operating conditions, incorporating the incomparable reliability and cleanliness of vibratory equipment.

Flexible conveying surface can be fabricated of various materials, including stainless steel, to successfully handle hot, sticky, fragile, or other “difficult to handle” materials. VIBRA-BELT? units are available in lengths up to 300 feet and in variable widths, depending on your application.

Ideal for materials that tend to stick to a metallic trough surface since a vibrating motion causes the suspended trough to flex, preventing material build-up.

Low profile, compact design fits where other conveyors cannot be installed.

No belt tracking problems or conveyor idlers to lubricate and maintain. Only a single vibratory conveyor eccentric drive requires periodic lubrication.

Material conveying speeds can be fixed or adjustable rate.

Dust tight and ventilated construction available.