E-WASTE RECYCLING SOLUTIONS

Precious metals extracted from e-scrap can bring in big money. General Kinematics engineers and manufactures vibratory processing equipment to enhance, separate, and maximize the purity level of these various commodities from e-Waste. Let our technical experts show you how.

GENERAL KINEMATICS ROD DECKS

General Kinematics Engineered Rod Decks are specifically designed for the separation of difficult material that is prone to sticking or blinding in traditional screening applications. The secret behind the rod decks ability to perform lies in the flexibility and reduced surface area of the rods within the deck section, while maintaining the designed screening tolerance. With more open area, less blinding, less hang ups, the heavy-duty design of GK rod decks allow for abrasive, heavy, wet, or otherwise difficult material to easily screen.

The high-stroke capabilities of the GK’s vibratory screening equipment combined with the flexibility of the engineered rod deck assemblies, creates a versatile and high performance screening solution to maximize sorting in your process application.

Rod deck media can be applied to various General Kinematics resource recovery equipment.

Separates material that blinds on traditional screening surfaces.

Allows for flexibility while maintaining screening tolerances.

GK Rod Decks allow for abrasive, heavy, wet, or otherwise difficult material to easily screen.

GK’S HIGH STROKE VIBRATING FEEDER

Cutting edge vibratory technology for enhanced material presentation

Challenged by our customers to do more within a limited footprint, General Kinematics developed the High Stroke Feeder (HSF) to create separation, improve on purity / recovery and increase the bottom line. GK’s HSF vibratory feeders improve on the presentation and recovery of various commodities by putting more energy into the material, thereby increasing separation of the various particles. In addition this spreads the materials across the width of the unit thereby resulting in enhanced material presentation for your optical sorter. General Kinematics has redefined the synergy between vibratory feeders and optical sorters.

HIGH STROKE FEEDER (HSF) PERFORMANCE ADVANTAGES:

High Stroke Creates Separation for Improved Purity

Faster Travel Speed = Better Material Separation = Optimal Recovery

More Energy Transmitted To the Material

Full Width Spread in Shorter Length

Lower Initial and Operating Costs

Dynamic Response to Negate Surge Loads

Up to 2/3 Less HP required to operate

OPTIONAL HSF FEATURES:

Specifically Engineered For the Industry

Optional Balanced Design Base

OEM Specific Models

Foot, Suspension or Combination Mounted Models

Mild Steel, Stainless Steel, Abrasion Resistant Steel Construction

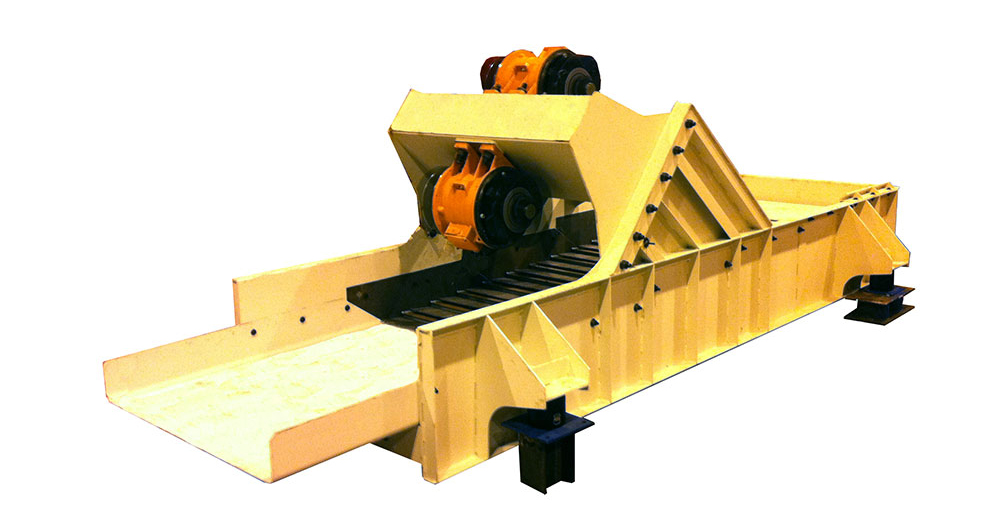

HD-HSF: HIGH DISPLACEMENT HIGH STROKE FEEDER

The latest vibratory technology for enhanced material presentation

Challenged again by our customers to do more within a limited footprint, General Kinematics has pushed the limits further and developed a High Displacement-High Stroke Feeder (HD-HSF) to create more separation, enhance purity levels, improve recovery and increase your bottom line. GK’s HD-HSF vibratory feeders improve the presentation of materials and recovery of various commodities by putting more energy into the material, thereby increasing separation of the various particles. In addition, this spreads the materials across the width of the unit thereby resulting in enhanced material presentation for your optical sorter. General Kinematics has redefined the synergy between vibratory feeders and optical sorters.

High Stroke Creates Separation for Improved Purity

Faster Travel Speed = Better Material Separation = Optimal Recovery

More Energy Transmitted To the Material

Full Width Spread in Shorter Length

Lower Initial and Operating Costs

Dynamic Response to Negate Surge Loads

Up to 2/3 Less HP required to operate

OPTIONAL HD-HSF FEATURES:

Specifically Engineered For the Industry

Optional Balanced Design Base which means no additional support structural work is required, thereby providing the best control, distribution and containment of materials

OEM Specific Models

Foot, Suspension or Combination Mounted Models

Mild Steel, Stainless Steel, Abrasion Resistant Steel Construction

SINGLE KNIFE DE-STONER? AIR CLASSIFIER

The GK Single Knife DE-STONER? Air Classifier is a fully proven design operating efficiently in various separating applications. This dry classifying system is capable of handling continuous, high volume production.

The completely dry system eliminates water handling and other “wet” system problems, yet can easily handle moist materials. The DE-STONER? Air Classifier combines vibration, fluidization with a high velocity / low pressure air stream to stratify material. Differences in terminal velocity of particles result in heavy items such as glass, metallics, and stones to be removed from lighter items such as paper, plastic and small wood.

The heart of your sorting system

Vibratory action moves material, with high density material settling to the bottom of the trough.

Fines drop out section (optional) removes smaller particle sizes like broken glass or dirt before reaching air fluidizer.

Air fluidizing section blows air through the material and creates turbulence to promote material stratification.

Material conveys over the air knife into the air stream. Heavier materials falls through the air stream to the discharge chute.

Marginal density material falls on the adjustable landing plate and drops back into discharge chute.

Lights materials are carried beyond the landing plate and convey to the end of the DE-STONER?.

Ultra light materials like thin film or paper are carried in the air stream to the product discharge zone.

Optional add-on’s include GK’s

Fluff Knife Upgrade or DE-STONER? Drop-Out Boxes.

SUCCESSFUL SEPARATING AND CLASSIFYING APPLICATIONS INCLUDE:

C&D materials

RDF fuel

Glass

Commingled materials

Shredded MSW

Shredded auto scrap fluff

Bio-mass fuel

The DE-STONER? Air Classifier uses air to separate heavy product from light product.

Environmental hazards associated with water separation is thus eliminated along with the inherent mess.

Easily adjustable to obtain varying degrees of separation.

Adaptable to a wide variety of products.

Separates material of different density, or of same density with different particle size.

Virtually jam-proof. No moving parts in contact with material flow.

Low energy demand with low HP motor and GK’s proven Two-Mass design.

Fully isolated design minimizes foundation requirements.

Heavy-duty, built to last construction.

MIXED METAL SORTING SYSTEMS

General Kinematics Mixed Metal Sorting Systems incorporates a tote dumper and vibratory metering feeder working in conjunction with a sorting conveyor. GK’s patented Flat Stroke Sorting Conveyor, reduces worker fatigue associated with noise and vibration in common transfer conveyors. This sorting conveyor is specifically designed with minimal vertical stroke for quieter operation while still conveying into multiple lanes. Material is loaded into the hopper and evenly metered to the sorting conveyor where workers are able to utilize the conveyor lanes to organize material types. Systems such as this equate to a better working environment for employees and better recovery of mixed metals.

FEATURES:Custom designed to fit your current tote configurations.

Operator controlled metering feeder.

Multiple lane configurations available per application.

Gentle shuffle action of material for reduced worker fatigue.