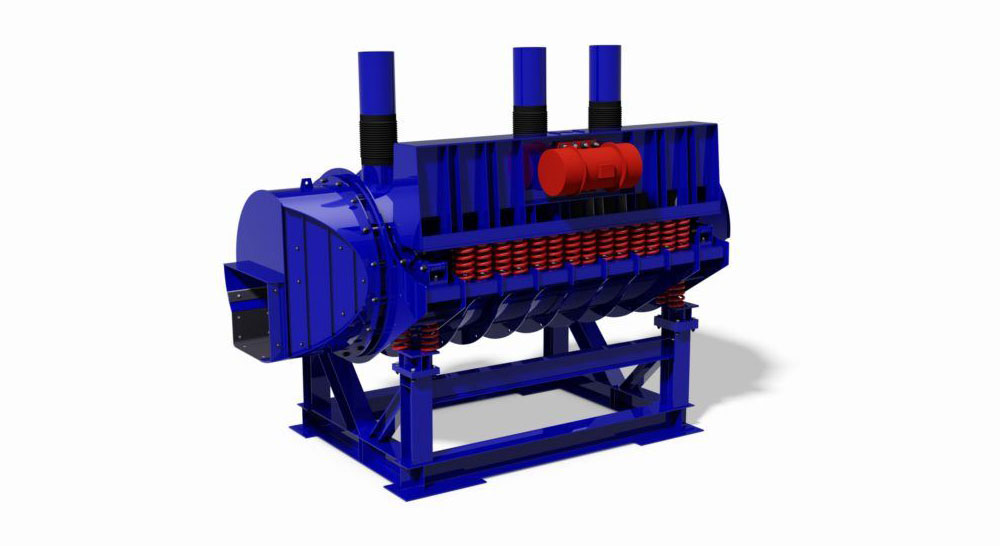

VIBRA-DRUM? DROSS RECLAMATION SYSTEMS

The General Kinematics VIBRA-DRUM? Dross Reclamation Mill quickly liberates precious metals from slag and dross, quickly recovering your valuable material. The VIBRA-DRUM? is able to be run in either a continuous or batch process through GK’s automated retention system. Optional lifting mechanism enables the drum to both quickly clean-out when run in batch form, but also allow for product retention time when run in a continuous flow. Combining these two variables allows for the maximum of flexibility, efficiency, and product mix.

FEATURES:

High energy vibration breaks down material up to 5 times faster than rotary or other types of reclamation devices.

Totally enclosed design eliminates dust and other contaminates from entering the work environment.

Small footprint minimizes space requirements, and no special foundations are required.

Bolt in, replaceable liner system is safe to install and can be quickly changed without special tools.

Able to run in both batch and continuous operation by use of pneumatic discharge door.

Air-bags provide an accelerated clean-out when run in a batch and utilized in an intermediate position to accelerate attrition of metallic fines.

By virtue of the increased attrition within the bed of the drum and the resultant generation of heat, material with moisture content will be more effectively handled than conventional or static methods of screening.

Continual removal of fines to remove cushioning effect of reduced material, increasing both capacity and grinding efficiency.

Utilizes a discharge perforated section to provide a secondary screening.

Low horsepower motors offer reduced power consumption.

Balanced design means minimal loading to foundation.

System can be utilized for a variety of functions present and future, such as coke fines removal.

Eliminates requirement of media for attrition.

Pneumatic discharge door allowing for release of batched material without the need for tools, machine lock-out/tag-out.