SHAKEOUT

NO-BAKE SHAKEOUTS

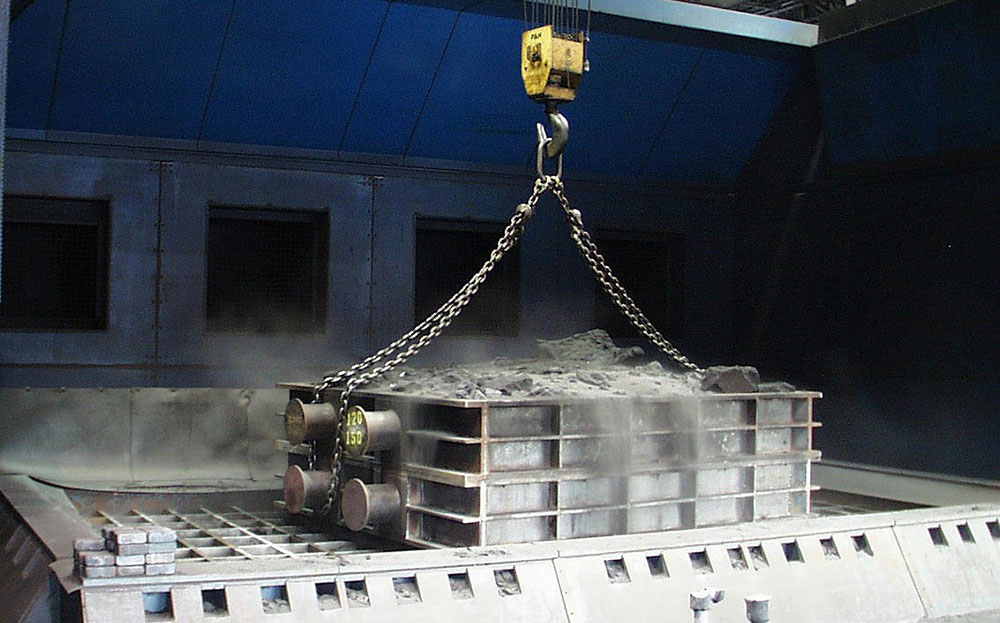

Designed to handle the world’s largest castings, General Kinematics No-Bake Shakeouts quickly and efficiently remove mold sand from castings. Unique Two-Mass design automatically compensates for varying load conditions, assuring non-dampening shakeout performance. Two-Mass technology allows GK to vibrate huge masses unlike conventional or old style direct drive shakeouts.

General Kinematics No-Bake Shakeouts or Two-Mass Vertical Shakeouts are capable of handling complete loads to 130,000 pounds (60 tons) or more. Used in the wind energy, marine, mining and heavy diesel industries.

No-Bake Shakeouts are dynamically balanced to reduce your foundation loading and prevent transmission of vibratory forces. Shakeout deck designs are custom engineered for your specific product and sand molding type.

Extremely low horsepower drives.

Easy maintenance of drive components, with extremely quick replaceability.

Capable of handling heavy and fragile castings.

Maximum sand separating efficiency.

Driven with proprietary sealed vibratory motors.

GK’s No-Bake Shakeouts eliminate the need for V-belts, pivoted motor bases, couplings, and large and expensive bearings.

Drive is mounted on a separate exciter mass, completely isolated from the high-intensity impact action of the shakeout deck.

VIBRA-CLAIM? SHAKEOUT / ATTRITION MILL

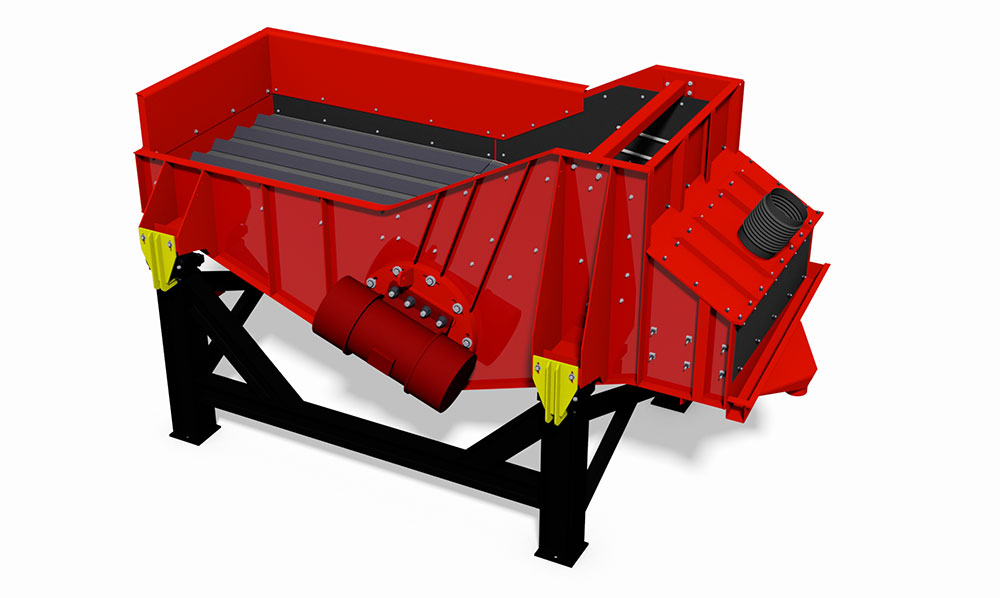

The VIBRA-CLAIM? Shakeout / Attrition Mill removes and reprocesses sand in one easy to use, easy to clean unit. By combining the high performance of GK’s proven shakeout design with the technologically advanced processing of our VIBRA-CLAIM? sand reclaimer, you can now accomplish all sand separation and reclamation in one efficient step.

The VIBRA-CLAIM? is a highly efficient shakeout and attrition mill that can eliminate the need for larger and more costly equipment. Proven design improves production rates and reduces costs for material handling and new sand. Equally important, the VIBRA-CLAIM? Shakeout / Attrition Mill recovers valuable non-ferrous materials when used in aluminum, bronze, brass and special alloy applications.

Vibratory action exposes the casting for removal, breaks down sand and creates the attrition for reclaim sand.

Screening of the reclaimed sand provides a grain size material for reuse. #8 and #12 mesh screens provided as standard.

Low head-room design does not require pits.

Attrition is based on GK’s proven VIBRA-MILL? technology.

High-energy Shakeout for increased throughput.

Available in standard and custom sizes and throughputs, depending on your sand binder system.

Standard Capacities, for Furan Sand: 7.5 TPH, 15 TPH, 27 TPH.

VIBRA-DRUM? SAND CASTING EQUIPMENT

Proven in hundreds of applications worldwide, VIBRA-DRUM? Sand & Casting Conditioners have revolutionized high volume mold/sand handling for foundry applications. This versatile Two-Mass system gently tumbles castings and provides accelerated casting cooling through equalizing of sand/casting temperatures and evaporation of moisture. This tumbling action reduces sand lumps to original grain size and blends sand to equalize shakeout sand temperature — all in one continuous, energy-efficient operation.

The gentle tumbling action of the VIBRA-DRUM? keeps the castings in a bed of sand, never dropping or creating impact during the shakeout process. This action provides the gentlest shakeout in the industry, allowing the automated shakeout of fragile castings.

The Two-Mass VIBRA-DRUM? delivers continuous shakeout operation, plus superior material motion for efficient sand and casting processing. Natural frequency vibration produces a beneficial drum-like material rotation that quickly reduces sand lumps without casting damage. High-frequency agitation efficiently reduces sand to original grain size. Put it all together and you have a simple, easy-to-maintain, non-rotating design with all the environmental benefits of a totally enclosed drum — but with no air handling, sealing, or interface problems and no casting damage.

Totally enclosed structure contains airborne silica and dust for a cleaner work environment.

The VIBRA-DRUM? brings controlled metallurgical cooling to castings for a better quality end product.

Non-rotation design is easier to feed, unload, hook up to your air handling system, and to maintain than competitive shakeout technologies.

The scrubbing action of the VIBRA-DRUM? produces cleaner casting surfaces, reducing shot blast consumable consumption up to 20%.

The two-mass drive system uses up to 2/3rd’s less energy compared to direct drive machines, creating substantial energy savings.

The gentle tumbling action in the sand bed helps protect castings from casting on casting surface damage. The net result is a significant reduction in scrap and rework post shakeout.

Springs: GK vibratory springs are designed for 24/7 continuous duty, and require little to no maintenance over the life of the machine. GK heavy-duty springs do not break or wear out under normal operation.

Parts: The natural frequency drums have few moving parts. Maintenance for sand casting equipment is contained to bearing lubrication and monitoring of motor and drive components.

Drive Force: Natural frequency vibration of the VIBRA-DRUM? produces a beneficial drum-like material rotation that quickly reduces sand lumps without casting damage. The tumbling action of the VIBRA-DRUM? scrubs the casting surfaces without sustaining casting damage.

Non-rotation design is easier to feed, easier to unload, and easier to maintain.

Heavy-duty liners are made of abrasion resistant wear plate to last.